The brewing itself is not a complex and complicated task. There are more and more homebrewers recently, but you need to know the differences in the systems you can use. Their purpose is to make your process more comfortable and less demanding. How is that useful for you?

Firstly, the brewing system relays significantly to a steady temperature you need for brewing. The temperature monitoring without any systems is time-consuming and can become dull and monotonous after a while. Therefore, it is obvious why RIMS vs. HERMS brewing systems are so popular and widely used.

What is Brewing?

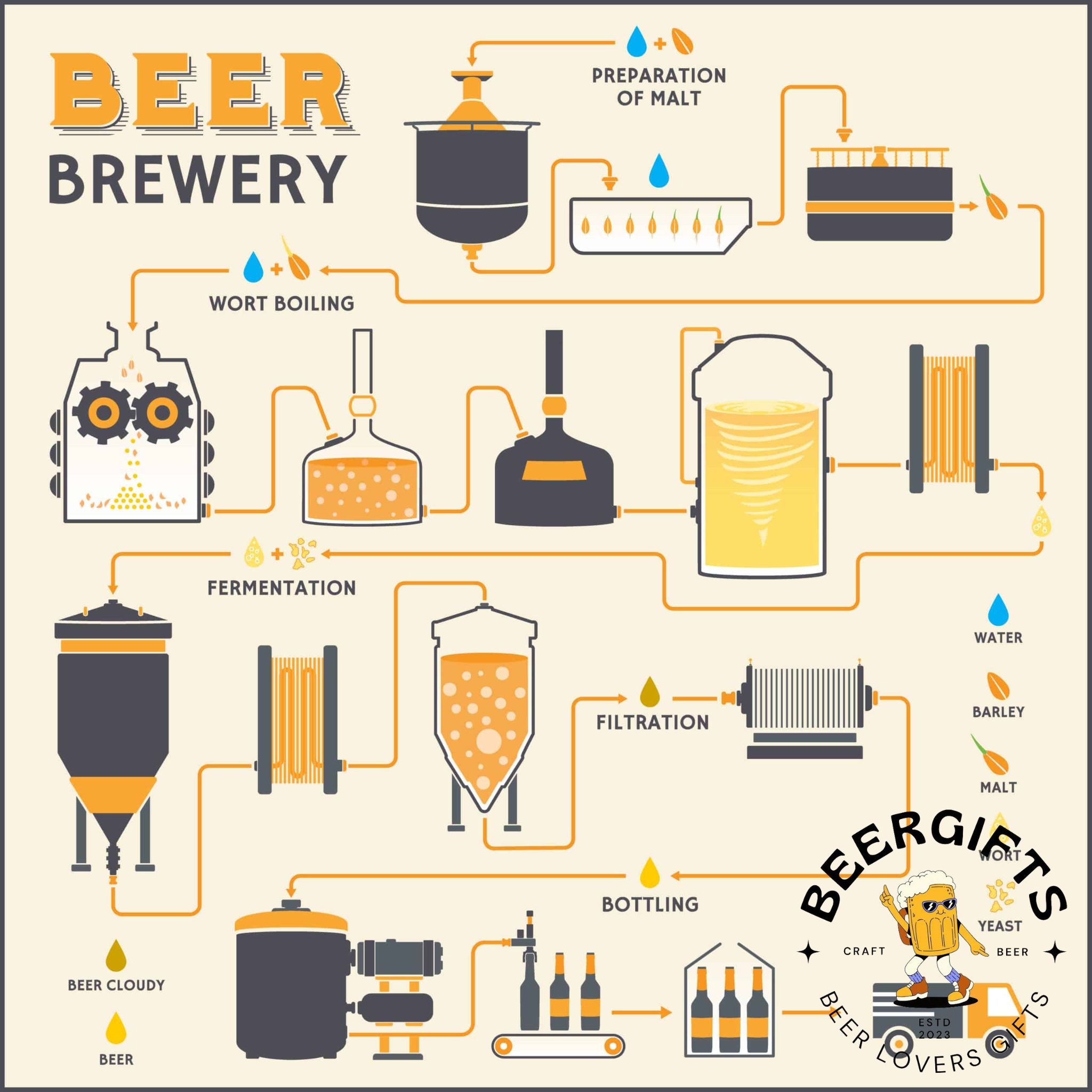

It is a process of producing beer. No matter if you have a big production in a beer factory or brew it at home, the process is basically the same.

It includes several phases like malting, mashing, lautering, boiling, fermenting, filtering, and many more. The first four stages are essential, while others can significantly differ from brewer to brewer.

Many contemporary brewers use syrups in the process. They are made of already prepared grains with extracted sugar, so the malting phase is more effortless and almost skipped. If you decide to use extracts or syrups, you should mix them with water before starting boiling.

Malting process

First, you should soak and crush the grains during the malting process. That way, they will be ready to expose to carbohydrates. When that being done, the mash process may start.

Mash process

When it comes to the mashing process, you can choose between the two most used systems to help you brew your beer correctly.

This process is the step in producing beer that includes fermentation, and it significantly depends on the temperature. Simple sugars released from the grains’ starches during the malting phase are now ready to be fermented.

It all happens in the big, specific vessel called the mash tun. You need to thoroughly mix hot water and melted grains until they create a so-called cereal mash. Then will start the saccharification process when the more complex molecules break down into more straightforward ones.

As a result, you will get the wort that is crucial in beer making. It is a liquid full of sugars that needs to go through another process, so-called lautering.

However, let’s get back to the mash process. Remember that it is crucial to stabilize the temperature. Only that way, everything will go the way you want it to. It has to be from 140 to 158 F (60 – 70 C) without many oscillations to make the process finish successfully. Otherwise, the wort can be ruined.

Now, when you have entirely understood the procedure before and during mashing, it is time to choose one of the two most common brewing systems, RIMS or HERMS.

RIMS vs HERMS Brewing Systems: Why Do you Need Them?

If you brew a small amount of beer, then moving and keeping the temperature the same during the mash process is not the problem. On the other hand, it can really become a problem to move it if you have more than 10 gallons (38 l) of mash.

Therefore, many brewers look for pumps to help them move the worth and allow it to circulate. It will help mix the content and prevent exposure of just one part of the worth to high temperatures.

Moreover, adding the pump leads to another great solution, controlling the temperature of the wort. In other words, RIMS and HERMS are systems that use pumps to circulate and move the wort, and they make the brewing process much more comfortable.

RIMS Brewing System

RIMS (Recirculating Infusion Mash System) is the heating system that works in an automated way rather than heating with a burner or any other heat source.

You don’t need to observe and control your temperature manually, but the automatic system will do it for you. That way, the inconsistency in temperature is highly regulated, and the risk of ruining the mash is minimal or none.

The system of working

The mash vessel or mash tun is connected with pipes and pumps to a RIMS tube. The liquid comes out of the mash tun and goes through the pump to the RIMS tube. Then, it flows through the RIMS tube and goes back to the same mash tun in the end.

The process is actually recirculating through the RIMS tube that includes a heating adapter and is connected to the thermostat. When the fluid goes through the heating adapter, it is automatically heated. If it is not necessary, it will turn off.

The thermostat is also automatic, and it can be adjusted to the temperature you need. As I have already mentioned, the mash temperature ranging from 140 to 158 F (60 – 70 C).

However, each brewer determines which temperature is the best for the specific recipe. That way, the thermostat will automatically turn off and on and adjust the fluid’s temperature coming through the RIMS tube according to the recipe.

So, there is no need to be worried and overwhelmed by the beer-making process. RIMS system will help you brew it in a more stable and controlled environment, meaning your beer will be of the same quality each time you brew it.

HERMS Brewing System

HERMS (Heat Exchanged Recirculating Mash System) is another system where the mash circulates using pumps rather than your energy. In this case, the process is a bit different.

In the HERMS system, everything happens in the same mash tun. There are no pumps and pipes that will take away and bring back the worth. Instead, the heating body is inside the heating liquid tun. The wort goes from the mash tun MLT (mash liquid tun) to the HTL (heating liquid tun).

The system of working

The coil, usually copper tubing, is inside the heating liquid tun, on the bottom, and the worth goes through the tubing. The vessel is filled with hot water, and the temperature is always under control.

As the wort circulates through the coil, it is being heated indirectly. The vessel is called HLT or hot liquid tank. The water is controlled and heated inside the tank, and there is a thermometer that is automatically controlled.

RIMS vs HERMS Brewing Systems: Pros and Cons

As you can see, both systems are based on circulation, heating, thermometers, and pumps, so they are pretty automated. Let’s see the pros and cons of both systems compared to other options you can find on the market.

Advantages of both systems compared to others

- Light beer – As the wort continuously circulates through the system, the produced beer is light.

- Temperature control – You can define and control the temperature more precisely in RIMS and HERMS than in other systems, meaning you are less prone to destroying the wort and losing money.

- Precise schedule – With HERMS and RIMS systems, you can quickly make larger amounts of beer, and you can also make it more often. You will be able to make the schedule and stick to it, as the process will always be the same.

- Consistency – Sooner or later, you will probably want to produce more beer. With these two systems, the production will always be consistent. You can be sure the beer quality will not fluctuate nor disappoint you.

Disadvantages of both systems compared to others

- Pumps – In the REMS system, the problem can occur when the pump breaks down, and the heat may destroy the worth. On the other hand, it can’t happen in the HERMS system as the beer is heated indirectly. In the case of pumps malfunction, the wort will be safe.

- Price – Budgeting can be the disadvantage of these two brewing systems. They cost at least a thousand dollars each, and it can be a big hit to your pocket if you are a beginner. Therefore, my recommendation is not to invest in the REMS and HERMS brewing systems if you change your hobbies pretty often.

- Space – HERMS system takes a lot of space and equipment. If you live in an apartment, it is not an excellent solution for you.

- Skills – Both systems require some basic knowledge of using heaters, thermometers, pumps, and other electrician equipment. In case you are not skilled and don’t have experience with setting systems like these, it is advisable to attend the course. You can also call an electrician to set up the system and help you out with it.

Summary

As you can see, using RIMS and HERMS systems in brewing has many advantages. Unfortunately, there is no right answer to the question of which one is better to choose. Both of them are equally practical and reliable, so the choice is only on you.

Therefore, you should look carefully at the equipment’s prices, the manuals, and instructions on setting the system and how to use it. Then, check out how much space you need to install the system. Once you have looked at all the variables and studied both systems, I am sure you will pick the best solution for your future hobby or profession. Cheers!